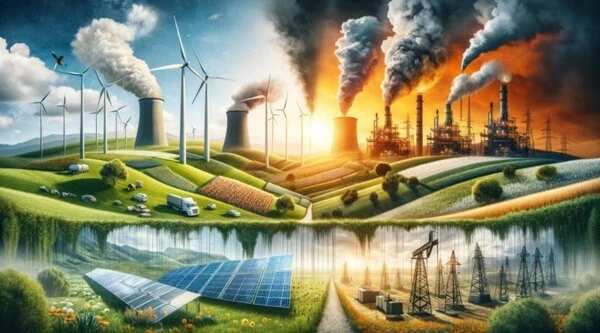

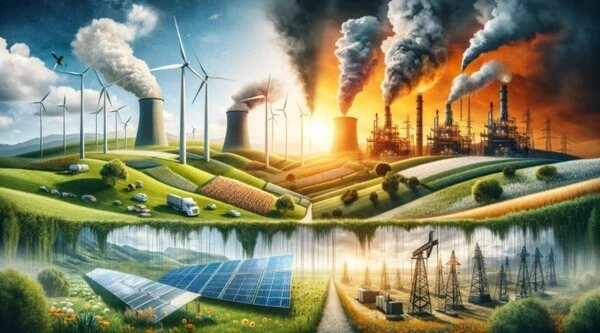

Renewable Energy in Textile Industry (solar, wind, bioenergy)

In 2025, the adoption of Renewable Energy in the Bangladesh textile industry has shifted from a "sustainability trend" to a survival strategy. Amidst rising gas prices and grid instability, factories are turning to solar, wind, and bioenergy to maintain their competitive edge and meet the strict Net Zero targets of global brands.

1. Solar Energy: The "Rooftop Revolution" Solar power is the most dominant renewable source in the sector. By late 2025, over 250 factories in Bangladesh have installed rooftop solar units, contributing significantly to the national target of 10% renewable energy. Rooftop Solar PV: Factories utilize their vast shed roofs to install photovoltaic (PV) panels. A typical large-scale factory can meet 20% to 30% of its daytime electricity needs through solar. Net Metering Policy: This allow factories to export excess electricity generated during holidays or weekends back to the national grid, receiving credit on their utility bills. Floating Solar: Some innovative factories with large water reservoirs or Effluent Treatment Plants (ETP) are piloting floating solar panels to save land space while reducing water evaporation.

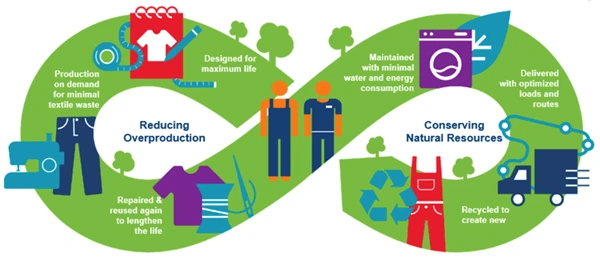

2. Bioenergy: Powering the Boilers Thermal energy (steam for dyeing) accounts for over 50% of a factory's total energy use. Traditionally powered by gas, bioenergy is the new eco-friendly alternative. Biomass Boilers: Factories are switching from gas or coal to boilers fueled by agricultural waste, such as rice husks, wood chips, and coconut shells. Waste-to-Energy (Jhoot): Innovations in 2025 are allowing factories to incinerate non-recyclable textile scraps (Jhoot) in specialized, high-tech boilers to generate steam, solving both the waste and energy crises simultaneously. Biogas: Large-scale factories are using anaerobic digesters to treat organic canteen waste and ETP sludge to produce biogas for cooking or supplementary power.

3. Wind Energy: The Coastal Frontier

While still in its early stages compared to solar, wind energy is gaining traction, particularly in the coastal belt (Chittagong and Mongla).

On-site Wind Turbines: A few coastal textile mills have installed vertical-axis wind turbines that can capture energy even from low-velocity winds common in the region.

Corporate PPAs: Under the 2025 Renewable Energy Policy, factories can now sign Power Purchase Agreements (PPAs) with off-site wind farms, allowing them to claim "Green Energy" usage even if they don't have turbines on their own roof.

Georgia Reader Reply

Et rerum totam nisi. Molestiae vel quam dolorum vel voluptatem et et. Est ad aut sapiente quis molestiae est qui cum soluta. Vero aut rerum vel. Rerum quos laboriosam placeat ex qui. Sint qui facilis et.